Premium AI advantage features

To Elevate Your Entire Construction Site.

Let our AI help you build faster and safer. That is how you save money!

1. Cara, our AI digital operator, is by your side with Safety and Efficiency Improvements

Did you watch her video above? If not, you should! Meet Cara, your Personal AI hoist operator. She analyses your hoist usage data and comes up with practical Efficiency and Safety improvements. Because you have no time to analyse data, we turn data into safety and efficiency suggestions

During the free trial month, you will see Cara every week to get an understanding of the possible improvements. After the trial, Cara will continue making monthly appearances, providing a solid data interval to keep things on track and keeping track of implemented improvements.

“Following up on efficiency items, response time is still around 30 seconds on average for over 300 calls this week. The primary reason for that is still waiting with doors open on the ground floor…” – Cara, your personal AI-assistant

2. Live AI-Camera

Leveraging the full potential of the AI analytics camera. The AI camera automatically detects when loading or unloading takes too long, captures video evidence of the completion of the daily checklist, captures video evidence of damages to the hoists, records any disputes occurring within the hoists, captures video evidence of incidents of material theft, and alerts you when the hoists start moving without an operator. But it can do much more! It offers real-time insights into your logistic operations, providing a comprehensive view of your operational landscape.

3. Measure Hoist Operator Performance

To keep track of the performance of the Hoist Operator and incentivize improvement, we track two major KPIs:

These insights are accessible via our BI portal, but per request, we can send an automated monthly report.

Especially when dealing with multiple hoists on a project, comparing how the hoist operators are doing is crucial for keeping everything running smoothly. We’re big on suggesting a bit of friendly competition – throw in some contests, and have them win lunches or a Bluetooth speaker. It gets the job done.

4. Smart Wait Feature

When the hoist is not being called, the Smart Wait feature will suggest to the Smart Algorithm what the next floor is with the highest likelihood of a call. This is all done based on AI calculations to your site-specific. For instance, towards the end of the day, it might suggest to the hoist operator to wait on a high floor, anticipating more downward movement. During lunchtime, it might be recommended the Operator hang around the level with the lunch area.

5. Prioritize Floors

For example, after lunch when everyone is gearing up to get back to work, who would you want to get to their floor first? It makes sense to prioritize the floors with the most workers or the most expensive ones. This way, the hoist stops where it’s needed most, avoiding unnecessary waiting times for specific groups. You wouldn’t want the expensive workers or the largest group to be left waiting the longest, right? That’s where prioritizing floors comes into play, making sure certain floors get precedence over others within the suggestions of the Smart Hoist Algorithm.

Prioritizing floors can be managed by logistic supervisors or construction managers through access to the BI portal. They have the control and visibility to set the priorities according to the site’s needs.

6. Locking Floors

This is a feature that we can use at multiple stages in the construction process. The functionality is that it sends out a real-time alert with a captured image when somebody enters a floor that you don’t want to be entered.

You can use it at the structural stage when the hoists are climbing floors without proper edge protection. Meaning you don’t want workers entering by hoists, because of safety reasons.

But what we see most often is that you set this feature up when you finished a floor, but the hoist cage doors are still there. You don’t want workers using the bathrooms of the newly finished apartments.

Construction managers can handle locking floors by the BI portal, granting them the authority and oversight to adjust priorities based on the requirements of the site.

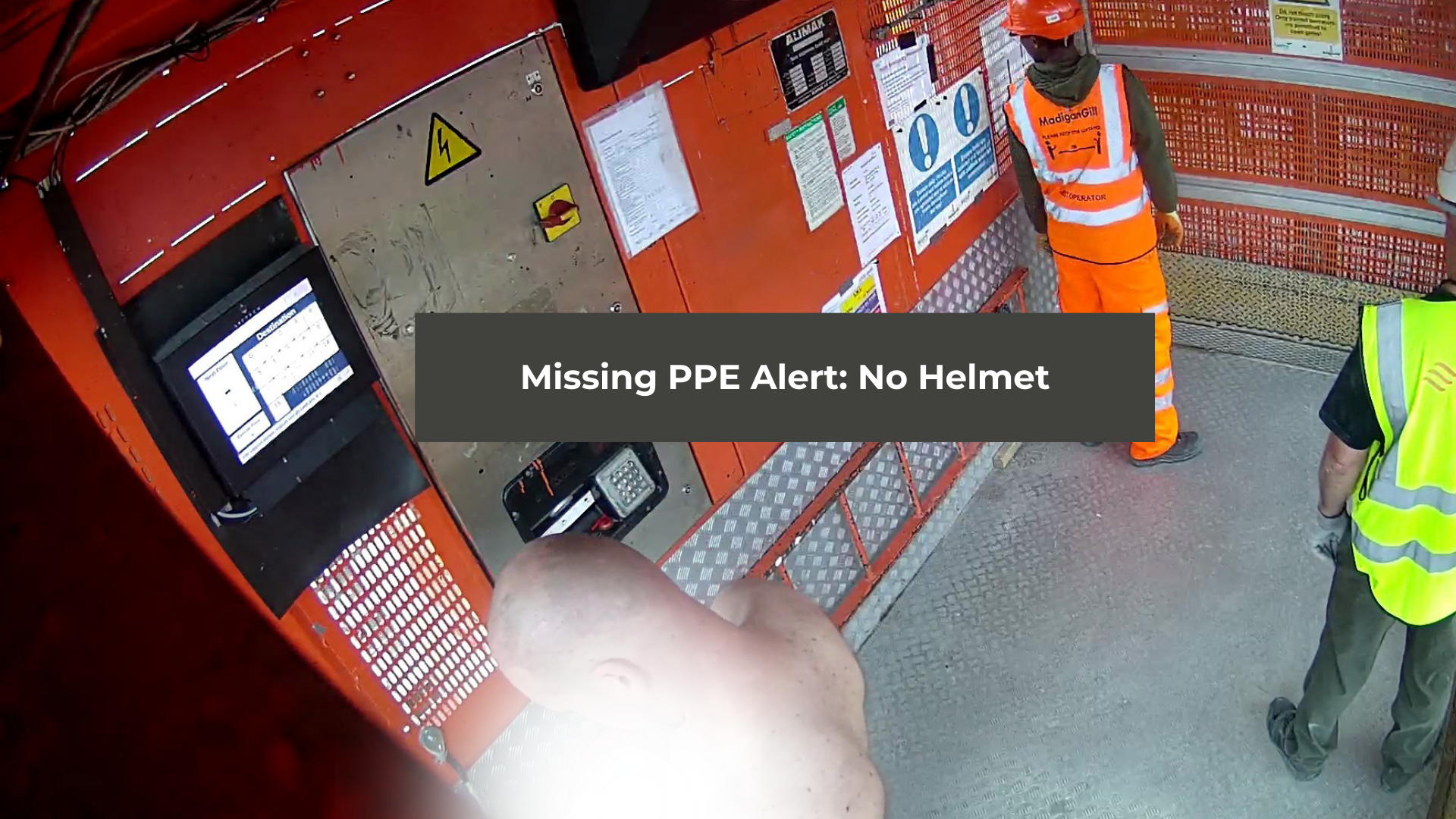

7. missing PPE-alerts with Pictures

Enhancing safety is a key element of the Smart Hoist System. To measure safety KPI’s we monitor people’s adherence to PPE rules on site. Our AI analytics camera is equipped to automatically identify instances where workers may be lacking essential PPE such as helmets, gloves, eyewear, and reflective vests. The system is so advanced that it recognizes turbans as an acceptable substitute for helmets.

In the event of a detection of someone without proper PPE in the hoist, the system promptly sends out alerts via WhatsApp or email, complete with a captured image. If frequent updates aren’t your preference, we can also arrange to send this information at other intervals – be it daily, weekly, or monthly. To provide some context, on average, we receive about 10 alerts per day regarding individuals lacking the necessary PPE. This indicates a potential for improvement on most sites.